The kitchen is usually called the heart of the house – a space for nourishment, accumulating, and generating Recollections. When creating or renovating this important space, aesthetics, functionality, and sturdiness are best priorities. on the other hand, an progressively important component, usually unseen but deeply felt, may be the effect of elements on indoor air high-quality. regular manufacturing procedures, specially for finishes, can release damaging chemical compounds into your home for months, months, or perhaps several years. This article delves into why deciding on cabinetry with eco-helpful coating processes, specially Those people minimizing risky natural and organic Compound (VOC) emissions, is not a niche choice but a elementary element of creating A really healthful and fashionable dwelling surroundings, specially when purchasing custom kitchen area cupboards.

Table of contents:

Unmasking VOCs: The Invisible risk in your house

The eco-friendly Evolution: Advancements in Coating Technology

Hallmarks of top-quality Eco-Friendly ending procedures

Breathe uncomplicated: The Tangible great things about very low-VOC cupboards for Indoor Air

A Sustainable decision: How eco-friendly Coatings advantage the World

The crystal clear difference: regular vs. Eco-welcoming Cabinet Finishes

recognizing the wholesome Kitchen Dream: Practical Applications

Unmasking VOCs: The Invisible risk in Your Home

just what are VOCs? risky organic and natural Compounds are a considerable team of chemical compounds present in numerous products and solutions we use to make and sustain our houses. These are termed 'volatile' as they effortlessly evaporate into your air at home temperature. Although some VOCs are Obviously transpiring, several guy-produced VOCs are concerning elements in paints, varnishes, adhesives, sealants, cleaning supplies, and engineered wood products – frequent elements in standard kitchen area cabinetry.

prevalent resources within cabinetry involve solvent-based mostly paints and lacquers, glues Employed in joinery or substrate manufacturing (like particleboard or MDF), and specified kinds of edge banding adhesives. the situation? Many of such VOCs are harmful to human health and fitness. brief-phrase exposure can result in problems, dizziness, nausea, eye, nose, and throat discomfort, and worsening of asthma symptoms. prolonged-time period or superior-concentration exposure is associated with extra intense health problems, together with respiratory illnesses, liver or kidney harm, central nervous technique effects, and also a heightened threat of particular cancers. small children, the elderly, Expecting Females, and men and women with pre-current respiratory conditions or chemical sensitivities are specially liable to the adverse effects of lousy indoor air quality stemming from VOC off-gassing. comprehension this hazard is the first step toward making healthier possibilities for your house.

The environmentally friendly Evolution: Advancements in Coating technological innovation

The good news is, rising awareness of wellness impacts and stricter environmental restrictions globally have spurred substantial innovation in coating systems. The sector has become steadily relocating clear of traditional, higher-VOC solvent-primarily based finishes towards A great deal safer, eco-friendly choices.

Solvent-based mostly Coatings: Historically dominant, these use natural solvents to dissolve and carry the complete elements. although offering longevity, they release sizeable amounts of VOCs all through application and curing.

Waterborne Coatings: These use water as the principal solvent, substantially decreasing VOC articles. Early versions faced challenges with durability compared to solvent-based solutions, but contemporary waterborne acrylics and polyurethanes present exceptional overall performance, toughness, and aesthetic good quality with significantly lower emissions.

UV-Cured Coatings: These finishes include monomers and oligomers that polymerize (harden) Practically instantaneously when subjected to ultraviolet (UV) gentle. This process releases hardly any, if any, VOCs. UV coatings are known for their Remarkable hardness, scratch resistance, and chemical resistance, producing them perfect for high-don surfaces like kitchen cabinets. The curing approach is likewise incredibly quick and Strength-successful.

Powder Coatings: Applied for a dry powder after which heated to fuse into a protecting layer, powder coatings consist of almost no VOCs. even though a lot more popular on metal, advancements are generating them increasingly feasible for wood-primarily based substrates.

This change can also be driven by worldwide environmental requirements. Regulations much like the California Air assets Board (CARB) period two specifications for formaldehyde emissions in composite Wooden merchandise and European E1 reduced-formaldehyde emission expectations have set benchmarks. top manufacturers globally now adhere to or exceed these benchmarks, recognizing that environmental duty and shopper health and fitness are paramount. Therefore, large-excellent cabinetry models are ever more adopting very low-VOC or zero-VOC finishing processes as an ordinary practice, signifying a commitment to superior solution good quality and person wellbeing.

Hallmarks of exceptional Eco-welcoming Finishing procedures

obtaining genuinely reduced-VOC and nutritious cabinetry consists of extra than simply switching paint varieties; it requires a holistic method of the producing and finishing course of action. Leading manufacturers devoted to health and sustainability ordinarily show many important characteristics:

product assortment: Prioritizing Qualified lower-VOC or zero-VOC coatings, which include high-grade waterborne lacquers or Innovative UV-cured finishes. In addition they often use very low-emission or formaldehyde-cost-free substrates (like certain grades of plywood or MDF).

Precision Application: using state-of-the-art application strategies (e.g., automatic spray strains, robotic arms) makes sure a uniform, constant coating thickness. This not merely enhances the aesthetic enchantment and longevity but also optimizes the curing procedure and minimizes substance squander.

comprehensive Edge Sealing: cupboard edges, especially All those of composite Wooden panels, is usually a supply of residual off-gassing with the core content or adhesives. High-top quality edge banding applied with precision using reduced-emission adhesives correctly seals these edges, avoiding VOC leakage and enhancing the general finish and longevity.

Controlled Curing: utilizing optimized curing processes, no matter if It is controlled drying environments for waterborne finishes or exactly calibrated UV light-weight exposure for UV coatings, makes sure the end hardens entirely and stably, minimizing residual emissions.

thorough Quality Manage: demanding testing and top quality checks through the production procedure validate not only the visual perfection and sturdiness of your end but also compliance with emission standards. This guarantees the ultimate merchandise delivered to The shopper is both of those wonderful and safe.

These integrated practices end in cabinetry that noticeably minimizes the introduction of dangerous substances into the home atmosphere.

Breathe quick: The Tangible advantages of Low-VOC cupboards for Indoor Air

quite possibly the most immediate and sizeable benefit of deciding on cabinetry with eco-welcoming finishes could be the good effect on your home's indoor air quality (IAQ). This translates into numerous tangible Advantages for homeowners:

speedier Occupancy & Less Disruption: contrary to classic cabinets That may require days or even months of aggressive ventilation to dissipate strong chemical odors (off-gassing), lower-VOC or zero-VOC cabinets release minimal emissions. What this means is it is possible to often use your new kitchen presently soon after set up, substantially decreasing the disruption and inconvenience connected with renovation.

lowered "New furnishings scent": That pungent chemical odor normally connected with new furniture or cabinets is essentially due to VOCs. Cabinets with eco-friendly finishes have a much more neutral scent, contributing to a far more pleasurable and welcoming quick surroundings.

A Haven for Sensitive people today: For households with younger young children, Expecting Gals, elderly members, or people today struggling from allergic reactions, bronchial asthma, or chemical sensitivities, reducing indoor air pollutants is significant. reduced-VOC cabinetry eliminates An important possible source of irritants, serving to to make a safer and much healthier residing Place for everybody.

extended-time period relief: Knowing that the lovely new kitchen is just not gradually releasing harmful chemical compounds offers priceless relief. It lets you totally take pleasure in your expense without having underlying wellbeing fears.

buying reduced-VOC customized kitchen cabinets is essentially buying the lengthy-phrase wellbeing and comfort of your family.

A Sustainable preference: How Green Coatings reward the Earth

some great benefits of eco-friendly coating procedures extend beyond personal residences towards the broader environment. Opting for very low-VOC cabinetry is actually a move towards far more sustainable residing and supports environmentally acutely aware producing:

Reduced Air Pollution: VOCs contribute to your development of floor-degree ozone (smog), An important air pollutant harmful to human wellness and ecosystems. utilizing lower-VOC finishes cuts down these emissions in the production phase and all through the solution's life.

decrease Carbon Footprint: Some eco-pleasant procedures, like UV curing, are hugely Vitality-economical when compared to the extended drying times and heat demanded for a few solvent-primarily based methods, contributing to minimized Electrical power intake and carbon emissions during generation.

considerably less harmful Waste: Waterborne coatings simplify cleanup with h2o rather than harsh solvents, and UV/powder coatings make fewer squander Total when compared with regular spraying solutions, cutting down the stress of harmful waste disposal.

Conference buyer desire & laws: By deciding upon merchandise with eco-friendly finishes, buyers generate demand for sustainable methods. This encourages more suppliers to undertake cleaner systems and adjust to significantly stringent environmental regulations around the world. Additionally, it improves a brand name’s popularity as dependable and forward-contemplating.

The distinct Distinction: conventional vs. Eco-Friendly Cabinet Finishes

to completely respect the buy kitchen cabinets from China main advantages of modern ending systems, it can help to check them with traditional solutions, Specifically more mature solvent-dependent coatings. the largest distinction is in VOC emissions: common coatings release substantial amounts of risky natural compounds through software and curing, when modern day alternatives like waterborne or UV-cured finishes emit incredibly small or practically zero VOCs.

This instantly impacts the off-gassing interval and odor. regular cabinets frequently demand weeks or perhaps months of air flow to remove strong chemical smells. In distinction, minimal-VOC cabinets have small odor, permitting for immediate or much faster use immediately after installation.

From a health and fitness perspective, substantial VOC information in common finishes could cause allergic reactions, respiratory issues, and pose lengthy-expression pitfalls. Eco-pleasant finishes tend to be safer, earning them ideal for homes with little ones, aged associates, or people today sensitive to chemical substances.

Environmentally, standard solvent-based processes add far more to air air pollution and harmful squander. Low-VOC possibilities lessen pollution, and technologies like waterborne coatings simplify cleanup, though UV curing is energy-successful, lowering the environmental impact.

Compliance with restrictions also may differ. Some regular products may wrestle to meet stricter world-wide standards like CARB period 2 or European E1. In distinction, eco-pleasant finishes from respected producers meet or exceed these benchmarks.

lastly, on sturdiness, when regular solvent-based finishes were long observed as probably the most sturdy, developments in waterborne and UV-cured systems now present equivalent or top-quality general performance in scratch, chemical, and moisture resistance. This eliminates the trade-off between sturdiness and well being, building lower-VOC finishes the very clear option for those prioritizing good quality and safety. For customers planning to acquire kitchen cupboards from China, a lot of leading suppliers now use these Superior, more healthy ending systems, presenting globally aggressive, Risk-free products and solutions.

acknowledging the balanced Kitchen desire: functional purposes

The need for much healthier home environments is mirrored in paying for decisions across numerous segments. reduced-VOC cabinetry is ever more specified for:

superior-finish household tasks: Homeowners investing significantly in personalized kitchen cupboards expect the best in both aesthetics and well being criteria.

wellbeing-aware Developments: Builders and builders focusing on wellness communities or LEED-Accredited properties prioritize elements with lower environmental and health and fitness impacts.

people with youngsters: mom and dad are acutely mindful of creating Safe and sound environments for their children, producing lower-VOC finishes a non-negotiable function for nurseries, playrooms, and relatives kitchens.

Renovations for Sensitive people: Homeowners managing allergy symptoms or respiratory problems actively look for out supplies that won't exacerbate their medical issues.

feed-back consistently highlights the real difference: designers report smoother undertaking handovers without shopper complaints about odors, builders respect Conference health and fitness standards very easily, and homeowners express substantial pleasure While using the immediate usability and comfy air top quality of their new kitchens.

deciding upon kitchen cupboards consists of a large number of decisions, from style and layout to supplies and components. nonetheless, the invisible element of ending know-how and its influence on indoor air top quality ought to be a primary consideration. Eco-pleasant coating procedures that lessen or reduce VOC emissions signify an important development, supplying a direct pathway to a much healthier dwelling environment with no compromising on sturdiness or attractiveness. It transforms the kitchen area from merely a functional Room right into a sanctuary that actually supports the wellbeing of its inhabitants.This dedication to wellness and sustainability is an indicator of forward-wondering brands. firms specializing in quality custom kitchen area cupboards, including UnionlandsCabinetry, realize this obligation. By integrating advanced low-VOC ending procedures into their production, they supply products that are don't just visually stunning and constructed to previous but additionally lead positively to creating more healthy, safer, plus much more fulfilling dwelling spaces for people around the world. This target represents far more than simply great production; it's a basic determination to the end-user's wellness and assurance.

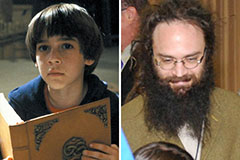

Rick Moranis Then & Now!

Rick Moranis Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!